Contamination and Erosion

Contamination and Erosion

All gas turbines experience losses in performance with time and the compressor has a significant impact. In a typical heavy duty axial compressor a 1.0% loss in compressor efficiency will create a 1.1% loss in output.

Compressor fouling is a serious concern and can be mitigated or recovered through proper operational practices. Dirt, oil and debris in the front stages of the compressor can result in a loss of mass airflow, and contamination in the last stages can result in power-robbing drops in the pressure ratio. These foreign objects can also erode or damage surface finishes and airfoil geometry, resulting in reductions in airflow and pressure ratios. Water-washing can partially clean contaminated blades, but recapturing full efficiency can only be achieved by opening the unit and mechanically cleaning the surfaces and replacing damaged components.

While the unit is open, the compressor can be coated to make the airfoils less susceptible to dirt and debris and increase the ability of the water wash to thoroughly clean the airfoils. Adding filtration to the inlet also helps maintain a clean compressor.

Leakage

In a typical heavy duty gas turbine compressor section, air is compressed to many atmospheres pressure by the means of a multiple-stage axial flow compressor. The compressor design requires highly sophisticated aerodynamics so that the work required to compress the air is held to an absolute minimum in order to maximize work generated in the turbine. Any changes to this precise geometry can materially affect performance.

Air leakage through and around components significantly rob performance. One example is a bleed valve which remains open during operation. Another would be a leak at the 4 way joint. While sealing the horizontal and vertical joints are necessary as the machine ages and the casing warps, sometimes all that can be done without purchasing new casings is to manage the leakage. Leaks are more costly to the aerodynamic cycle at stages further down the axial compressor. A leak at an early stage might not be worth the cost of repair.

At the tail end of the compressor rotor is the inner barrel, which provides the inner diameter flow path and the internal support for the exit guide vane (EGV’s). On the internal surface of the inner barrel there is a labyrinth seal called the high-pressure packing seal. On field inspections we often find significant rubbing of the rotor to the labyrinth seals of up to 90 mils. This excess clearance and thus increased airflow results in a loss in performance.

This leakage can be minimized by retrofitting the high-pressure packing seal area with a wire brush seal. The wire brush seal is flexible and will deflect (not wear) if it does contact the rotor. The bristles of the brush deflect in the direction of rotation so that a closer effective clearance can be maintained. The seal even remains intact during transient events where some vibration occurs. Also, there will be less performance degradation over time since the wire brush will bounce back to the original configuration after contact. These losses can only be repaired during an overhaul.

Calibration

Air temperature and pressure can seriously affect performance. Since the gas turbine is an air-breathing engine, its performance is changed by anything that affects the density and/or mass flow of the air intake to the compressor. When measuring performance degradation over time, remember to correct for changes to the reference conditions of 59 F/15 C and 14.7 psia/1.013 bar. Differing ambient air temperatures affect the heat rate. Correction for barometric pressure is more straightforward. A reduction in air density reduces the resulting airflow and output proportionately, but the heat rate and other cycle parameters are not affected.

Humidity is an often overlooked factor affecting performance. Humid air, which is less dense than dry air, also affects output and heat rate. In the past, this effect was thought to be too small to be considered. However, with the increasing size of gas turbines and the utilization of humidity to bias water and steam injection for NOx control, this effect has greater significance.

TGM can help you assess your unit’s existing performance versus its original design and establish a performance measurement process to accurately capture decreases which could indicate the onset of serious problems.

Turbine Generator Maintenance can help you achieve your goals in restoring your machine to its new and clean condition or upgrading its performance to achieve higher output, lower emissions or both.

Emergency Stop Valve Inspection

/in News, Project Spotlight /by Mike.LakeWe recently received a call from a paper & pulp producer in the Southern U.S. to assist them with an emergency stop valve they were having issues with. Obviously an important safety component to any turbine, we immediately mobilized a Technical Field Advisor to assist in identifying the root cause and developing a path forward. The inspection revealed a broken retaining ring inside the stop valve. We had a new retaining ring manufactured, stop valve re-assembled, and assisted with unit start-up all in just over 24 hours, allowing the plant to get back online as soon as possible. This was another example of our quick emergency response times when there is a customer in need.

Gas Turbine Compressor Degradation

/in Combustion Turbine Tips, Turbine Tips /by Mike.LakeAll gas turbines experience losses in performance with time and the compressor has a significant impact. In a typical heavy duty axial compressor a 1.0% loss in compressor efficiency will create a 1.1% loss in output.

Compressor fouling is a serious concern and can be mitigated or recovered through proper operational practices. Dirt, oil and debris in the front stages of the compressor can result in a loss of mass airflow, and contamination in the last stages can result in power-robbing drops in the pressure ratio. These foreign objects can also erode or damage surface finishes and airfoil geometry, resulting in reductions in airflow and pressure ratios. Water-washing can partially clean contaminated blades, but recapturing full efficiency can only be achieved by opening the unit and mechanically cleaning the surfaces and replacing damaged components.

While the unit is open, the compressor can be coated to make the airfoils less susceptible to dirt and debris and increase the ability of the water wash to thoroughly clean the airfoils. Adding filtration to the inlet also helps maintain a clean compressor.

Leakage

In a typical heavy duty gas turbine compressor section, air is compressed to many atmospheres pressure by the means of a multiple-stage axial flow compressor. The compressor design requires highly sophisticated aerodynamics so that the work required to compress the air is held to an absolute minimum in order to maximize work generated in the turbine. Any changes to this precise geometry can materially affect performance.

Air leakage through and around components significantly rob performance. One example is a bleed valve which remains open during operation. Another would be a leak at the 4 way joint. While sealing the horizontal and vertical joints are necessary as the machine ages and the casing warps, sometimes all that can be done without purchasing new casings is to manage the leakage. Leaks are more costly to the aerodynamic cycle at stages further down the axial compressor. A leak at an early stage might not be worth the cost of repair.

At the tail end of the compressor rotor is the inner barrel, which provides the inner diameter flow path and the internal support for the exit guide vane (EGV’s). On the internal surface of the inner barrel there is a labyrinth seal called the high-pressure packing seal. On field inspections we often find significant rubbing of the rotor to the labyrinth seals of up to 90 mils. This excess clearance and thus increased airflow results in a loss in performance.

This leakage can be minimized by retrofitting the high-pressure packing seal area with a wire brush seal. The wire brush seal is flexible and will deflect (not wear) if it does contact the rotor. The bristles of the brush deflect in the direction of rotation so that a closer effective clearance can be maintained. The seal even remains intact during transient events where some vibration occurs. Also, there will be less performance degradation over time since the wire brush will bounce back to the original configuration after contact. These losses can only be repaired during an overhaul.

Calibration

Air temperature and pressure can seriously affect performance. Since the gas turbine is an air-breathing engine, its performance is changed by anything that affects the density and/or mass flow of the air intake to the compressor. When measuring performance degradation over time, remember to correct for changes to the reference conditions of 59 F/15 C and 14.7 psia/1.013 bar. Differing ambient air temperatures affect the heat rate. Correction for barometric pressure is more straightforward. A reduction in air density reduces the resulting airflow and output proportionately, but the heat rate and other cycle parameters are not affected.

Humidity is an often overlooked factor affecting performance. Humid air, which is less dense than dry air, also affects output and heat rate. In the past, this effect was thought to be too small to be considered. However, with the increasing size of gas turbines and the utilization of humidity to bias water and steam injection for NOx control, this effect has greater significance.

TGM can help you assess your unit’s existing performance versus its original design and establish a performance measurement process to accurately capture decreases which could indicate the onset of serious problems.

Turbine Generator Maintenance can help you achieve your goals in restoring your machine to its new and clean condition or upgrading its performance to achieve higher output, lower emissions or both.

Combined Cycle Users Group

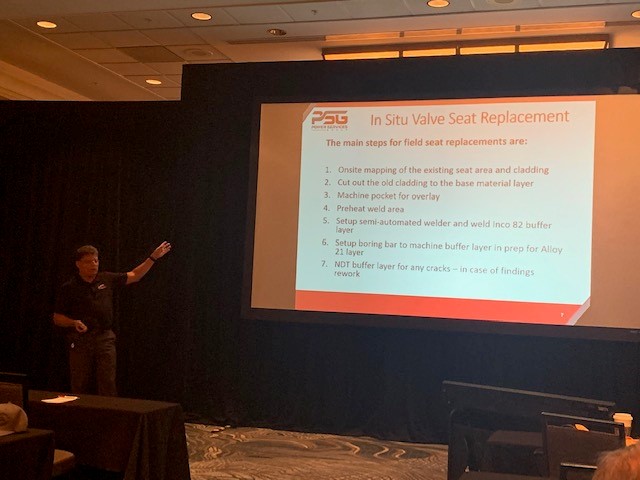

/in Events /by Mike.LakeWe had another amazing conference. Here our own Joerg Schoepp, GM of Repair Services for PSG,

is seen presenting an enthralling informative about In Situ Valve Seat Replacement.

American Nuclear Society Utility Working Conference and Vendor Technology Expo

/in Events /by Mike.LakeANS was amazing! We met a lot of people and gained immense amounts of information. Can’t wait for next year!

Happy Independence Day!

/in Events /by Mike.LakeHave a safe and happy Independence Day! our offices will be closed on July fourth and fifth.

70th Annual AREGC

/in Events /by Mike.LakeAREGC was in full swing this year in Point Clear, Alabama. Mike Lake and Gary Beck had an amazing time getting to network and meet all of our new customers!

The Grand Hotel Marriott in Point Clear Alabama for the Grand Hotel. Christmas and for use in Alabama Magazine Nov. Dec 2018

2019 Usa Executive Summit

/in Events /by Mike.LakeThe 2019 executive summit allowed for a lot of knowledge to be exchanged! Our own Keith Ravan and Mike Ballard spearheaded this conference and had so much fun! can’t wait for the 2020 conference.

Frame 6 Users Group Conference

/in Events /by Mike.LakeGary Beck and Lance Birkenholz spearheading the Frame 6 Conference this year in California!

7F Users Group Conference 2019

/in Events /by Mike.LakeWe are Going to be at the 7F Users Group Conference this year! It’s being held in gorgeous and centrally located Schaumburg, Illinois at the Renaissance Schaumburg Convention center. Come see Melissa, Mike, and Mr. Turbine at booth #23! we look forward to seeing you and helping you with your Turbine project needs!

Combustion Turbine Operations Technical Forum Spring 2019

/in Events /by Mike.LakeThe Spring CTOTF conference was a success! It was nice meeting everyone and getting to discuss combustion engines! A big thanks to our giveaway winner!